When you understand the terminology behind garage flooring, you immediately gain an edge. You can spot inflated claims, recognize missing steps, and avoid paying for systems that won’t survive East Pennsylvania’s moisture, road salt, or freeze/thaw cycles. Here are the terms that help you separate real quality from marketing spin.

Epoxy Coatings

Epoxy is a two-component material that cures into a thick, highly adhesive layer. Professionals use epoxy for primers and broadcast coats because it bonds deeply to concrete and provides the structural strength of the system. If an installer calls everything “polyaspartic,” they may be skipping crucial epoxy layers to speed up installation.

Moisture Mitigation

Concrete constantly releases moisture vapor, and in a region with year-round humidity and winter melt-off like East PA, vapor pressure is a major cause of coating failure. Moisture mitigation means applying a moisture-mitigating epoxy primer that forms a vapor barrier. Reputable 2-day systems include this step; many 1-day systems skip it because it slows the process down.

Concrete Paint

Low-cost contractors sometimes use this term to blur the line between paint and real coatings. Concrete paint is thin, purely cosmetic, and not engineered for hot tires, salt, water, or freeze/thaw cycles. If a company uses “paint” and “coating” interchangeably, that’s a sign they’re not offering a professional system.

Polyaspartic

A fast-curing, UV-stable clear topcoat known for its strength and chemical resistance. Polyaspartic protects the flake and epoxy layers beneath it and keeps the system looking sharp. But here’s what informed buyers know: polyaspartic is a topcoat—not a replacement for epoxy or moisture mitigation. Any installer claiming otherwise is overselling.

Polyurethane

Another type of clear protective finish. Though durable, polyurethane generally provides lower UV stability and chemical resistance compared to polyaspartic. It’s acceptable in some specialty environments, but for garage flooring exposed to sunlight and winter runoff, polyaspartic is the superior choice.

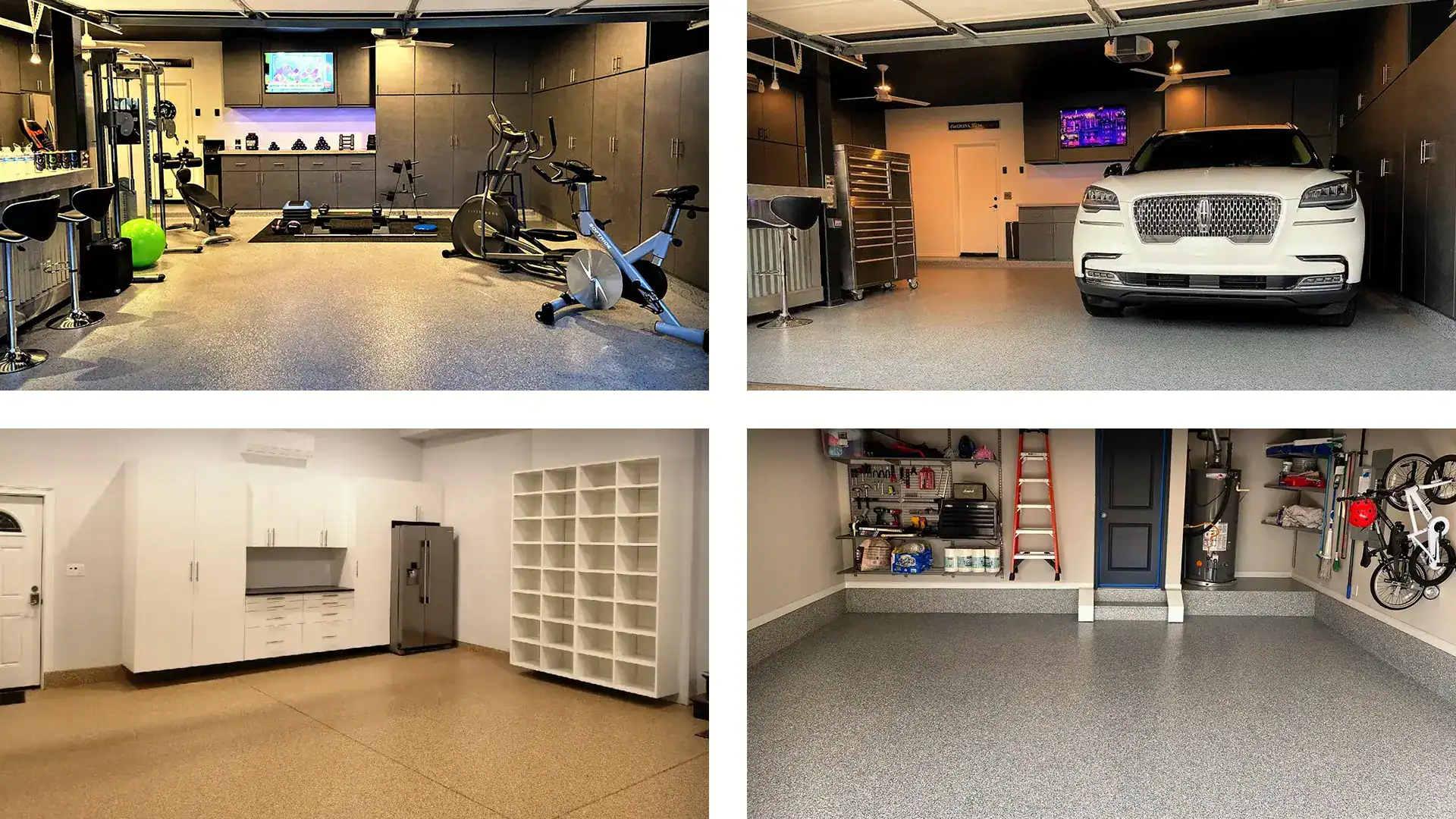

Flake/Full-Flake

In a professional flake epoxy system, colored polyvinyl acetate (PVA thermoplastic) and/or mica mineral flakes are broadcast into the wet epoxy to add visual depth, traction, and texture. A full-flake installation covers the entire surface, creating a thicker, more uniform finish that stands up to heavy use—ideal for East PA garages exposed to snow, salt, and moisture.

Garage Floor Coating

A true garage floor coating consists of multiple layers working together: a moisture-mitigating epoxy primer, full-flake coverage, and a polyaspartic topcoat (high quality coatings use 100%-solids polyaspartic and may apply more than one coat). If any of these layers are missing, you’re not getting a long-lasting system—no matter how convincing the sales pitch sounds.

Ready for garage flooring built to handle East Pennsylvania conditions? East PA Garage Floor Coating installs durable, high-performance systems designed for real-life wear. Request your free quote today.