In this guide, we’ll explore the most common coating language you’ll come across in the epoxy flooring industry. These terms are grouped by category for easy reference.

Coating Language: Coating Types

- Epoxy Coating: One of several types of two-component (Part A resin & Part B hardener) coatings that are mixed and applied to concrete. Epoxies are slow-cure, high-build coatings (they can be applied thickly). Consequently, when mixed, they form a thick, durable, chemical-resistant surface. Albeit, epoxies can fade and amber when exposed to UV light. As such, epoxies are best used as primer coats (direct-to-concrete) for garage floors or as color coats for interior installations.

- Polyaspartic: A fast-curing 2-component coating providing extreme UV and chemical resistance. Hence, polyaspartics are ideal as topcoats for spaces exposed to UV or chemicals (like automotive fluids). However, these coatings are very poor as direct-to-concrete primers in the presence of medium to high moisture levels. They are best used as topcoats in conjunction with an epoxy primer coat.

- Polyurethane: A flexible color coat that resists UV rays, chemicals, and abrasions. Hence, these coatings are often used as a final protective layer over epoxy (e.g., for exterior patios). However, polyurethanes can be odorous and are not for use in garages due to their susceptibility to plasticizer migration (i.e., staining from hot tires).

Coating Language: Decorative Systems

- Flake System: A coating system incorporating thermoplastic or mica “flakes” to enhance the system’s appearance, texture and depth. Flakes also provide some slip resistance (albeit, an anti-skid aggregate should still be added to the final clear topcoat for safety).

- Mica: Natural mineral stone flakes that are added to a flake blend to provide an enhanced reflective quality. Flake blends incorporating mica stone are often used in higher-end floor coating systems.

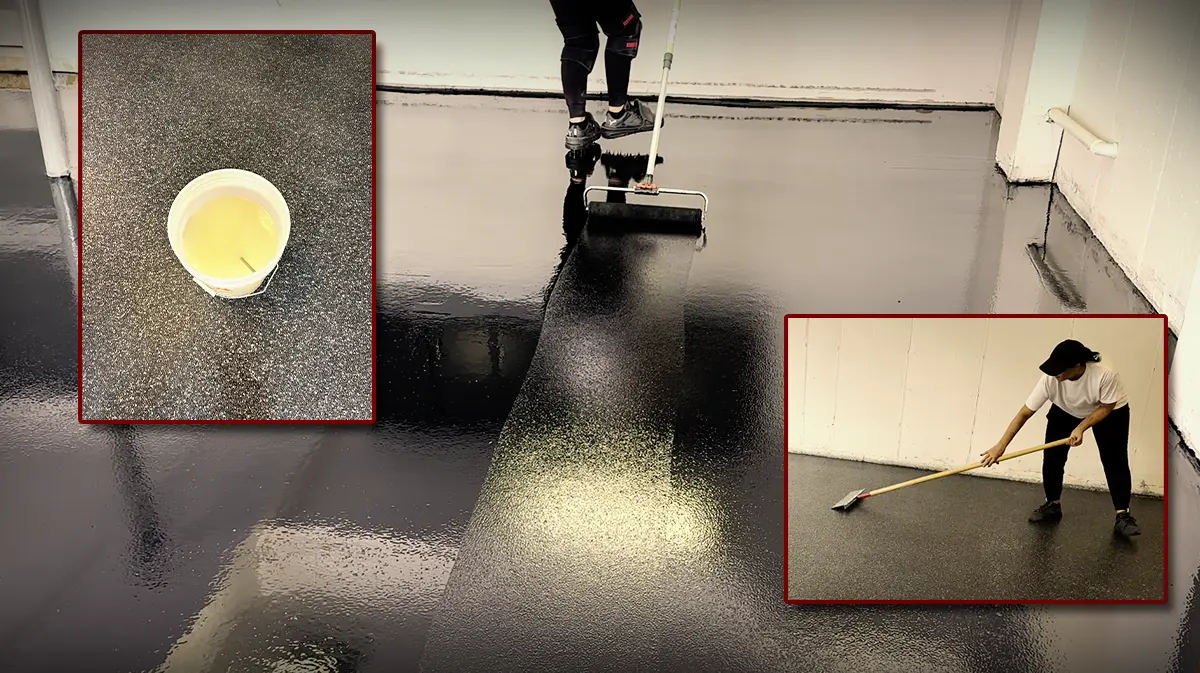

- Full Flake Coating: A system where the flake blend is broadcast into the “wet” primer coat in a full-flake spread. That is, the flakes are broadcast “to rejection”. Full flake epoxy and polyaspartic flooring create the thickest, most durable systems. Perfect for garages and commercial spaces requiring maximum durability and aesthetic appeal.

Coating Language: Functional Terms

- Moisture Mitigation: The process of controlling moisture vapor transmission to prevent damage like peeling or delamination of floor coatings.

- Waterproofing Basement: Applying moisture-resistant coatings, such as a moisture-mitigating epoxy, to prevent water infiltration and protect basement floors..

Miscellaneous:

- Metallic Epoxy Floor: A high-gloss, decorative floor coating with added metallic pigments that create a three-dimensional, marbled effect. Popular in both residential and commercial settings where high-impact is desired.

- Concrete Floor Paint / Concrete Paint: Sometimes used to refer to paint made for concrete. Albeit, paint is a poor floor coating option. Also a colloquial term for concrete coatings.

- Garage Floor Coating: Another layman’s term for various types of epoxy and polyaspartic coatings. Garage floor coatings consist of multiple layers of coatings, typically an epoxy base (primer) coat and one or more polyaspartic topcoats.

Conclusion

Understanding these common terms ensures you’re equipped to make informed decisions about your epoxy flooring project. Whether you’re looking for durability, aesthetic customization, or moisture resistance, these key concepts will help you navigate the world of garage floor coatings in Pennsylvania.