Coating systems are getting increasingly popular throughout Pennsylvania. Homeowners and businesses want visually pleasing floors that can withstand yearly wear and tear with minimal maintenance, and concrete coating systems fit the bill nicely. However, like any advanced, quality improvement to a space, it comes with all sorts of terms and questions that are worth answering. So understanding coating systems is the key to making the right choice.

Coating System Categories

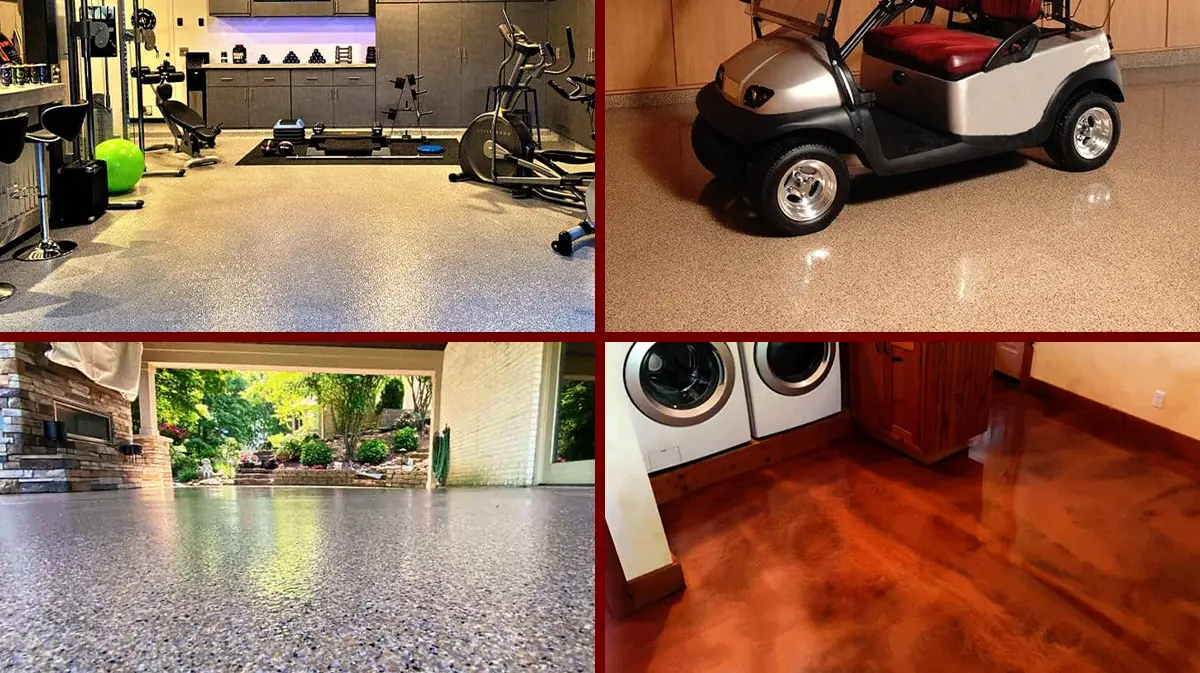

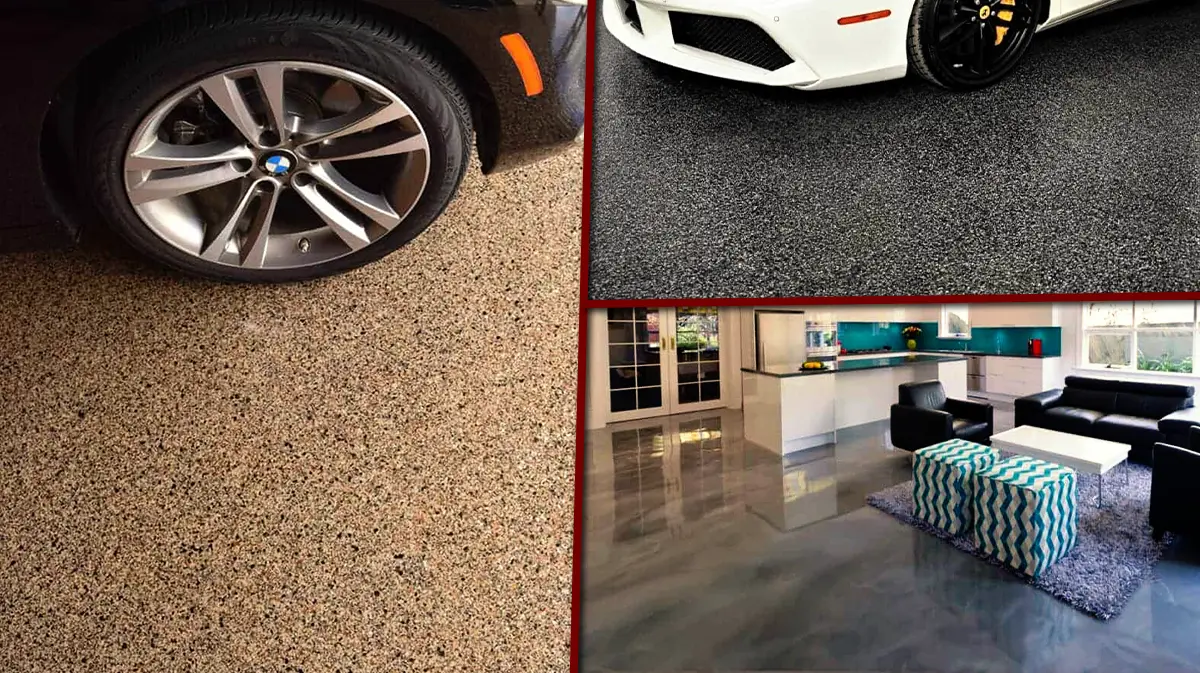

Coating systems typically fall into one of four categories:

- Solid Color: As the name implies, solid color coating systems are “flakeless” and solid in color. Two to three layers of coatings, 8 to 12 mils thick (a “mil” is a unit of thickness equal to 1/1000 of an inch).

- Partial Flake: Depending on the style selected, partial flake coating systems provide a light to heavy sprinkling of flakes. These are two to three layered coatings, 15 to 18 mils thick.

- Full Flake: Coating systems with a full-flake spread (the flakes are broadcast to “rejection”). Three to four layered coatings, up to 30 mils thick and beyond.

- Metallic: Two to three layered coating systems with a flowing, 3-D marbled look and iridescent accents. Not recommended for garages or high-traffic areas.

The installation process for each coating system type varies slightly, but there’s a lot of overlap. In partial and full flake systems, the flake blends are mixtures of different colored 1/8″ or 1/4″-sized thermoplastic flakes. We take it a step further by incorporating natural mica stone flakes in our blends for added reflectivity. Generally speaking, the fuller the flake spread, the thicker the coating (of course, the number of applied coatings affects thickness too). Needless to say, thicker coatings provide more durability. Flaked systems that incorporate thermoplastic or mica flakes, add color, contrast, and texture, offering a variety of aesthetic options.

Choosing the Right Coating System

Selecting the appropriate coating system is crucial and depends on various factors such as exposure to UV light, chemical stains, aesthetics, odor sensitivity, return to service duration, and cost. For example:

- Driveways: Need UV, stain and chemical resistant coatings.

- Garages: Require moisture-mitigating, UV, stain, and chemical-resistant coatings, including a high-end top coat for resistance to hot-tire transfer (aka “plasticizer migration”).

- Patios and walkways: Require UV and scratch-resistant coatings.

- Indoor Spaces: Might prioritize aesthetics and odor sensitivity.

- Basements: Moisture-mitigating and stain resistant coatings.

- Commercial spaces: fast return-to-service duration; interior spaces require impact (high-traffic), stain and chemical resistance, while exterior spaces require all that and UV resistance as well.

A thorough evaluation of the space by both the customer and a professional installer ensures the right choice.

Understanding Coating Systems: Why Professional Installation Matters

Professional installers bring expertise and experience, ensuring that the coating system selected and the coating products used are appropriate for the space. This meticulous approach helps avoid common pitfalls and guarantees a high-quality finish. long-lasting durability, and beauty. A seasoned, local professional is going to be the fastest route to choosing the right coating system for your space.

If you see anyone promoting “1-day polyurea systems” and DIY epoxy kits from hardware stores — beware. These are rush jobs that will have you scratching your head as your new floor cracks and peels, often within months. One-day systems often fail because they use a fast-curing polyurea as the primer (to ensure the job gets done in a day). Not a great idea if the concrete measures medium to high-level moisture content. Under these conditions, these fast-cure coatings cure even faster, providing insufficient time to penetrate and bond with the concrete substrate. (They’re great topcoats, but lousy direct-to-concrete primers).

In contrast, our two-day systems use a slower-curing, moisture-mitigating epoxy primer (a moisture vapor barrier) on the first day, which deeply penetrates the concrete. The chosen flake blend is then broadcast into this layer. After a full day of curing, the second day focuses on applying dual polyurea-polyaspartic top coats. This thorough approach produces a thick, 4-layered coating system, ensuring long-term durability and resistance to environmental stressors.

The Advantages of Multiple Coats

Using multiple coats of various products like epoxies, polyurethanes, and polyurea-polyaspartics creates robust coating systems. These systems not only enhance the floor’s appearance but also provide significant protection against wear and tear, significantly extending the floor’s lifespan.

By understanding the different types of coating systems and the importance of professional installation, homeowners and businesses in Pennsylvania can make informed decisions that enhance the functionality and aesthetics of their floors.